2200 m²

lab spaces

Facilities

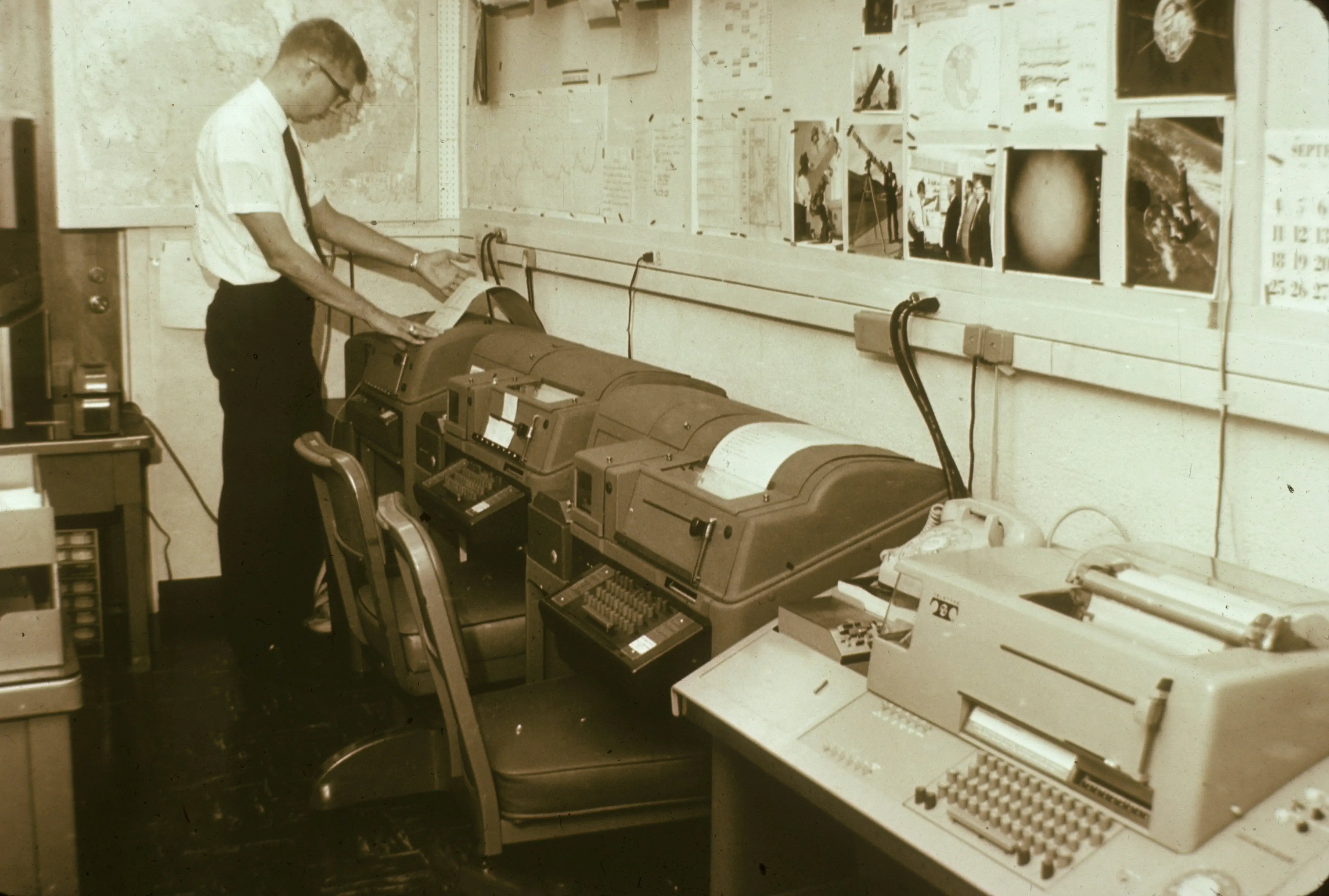

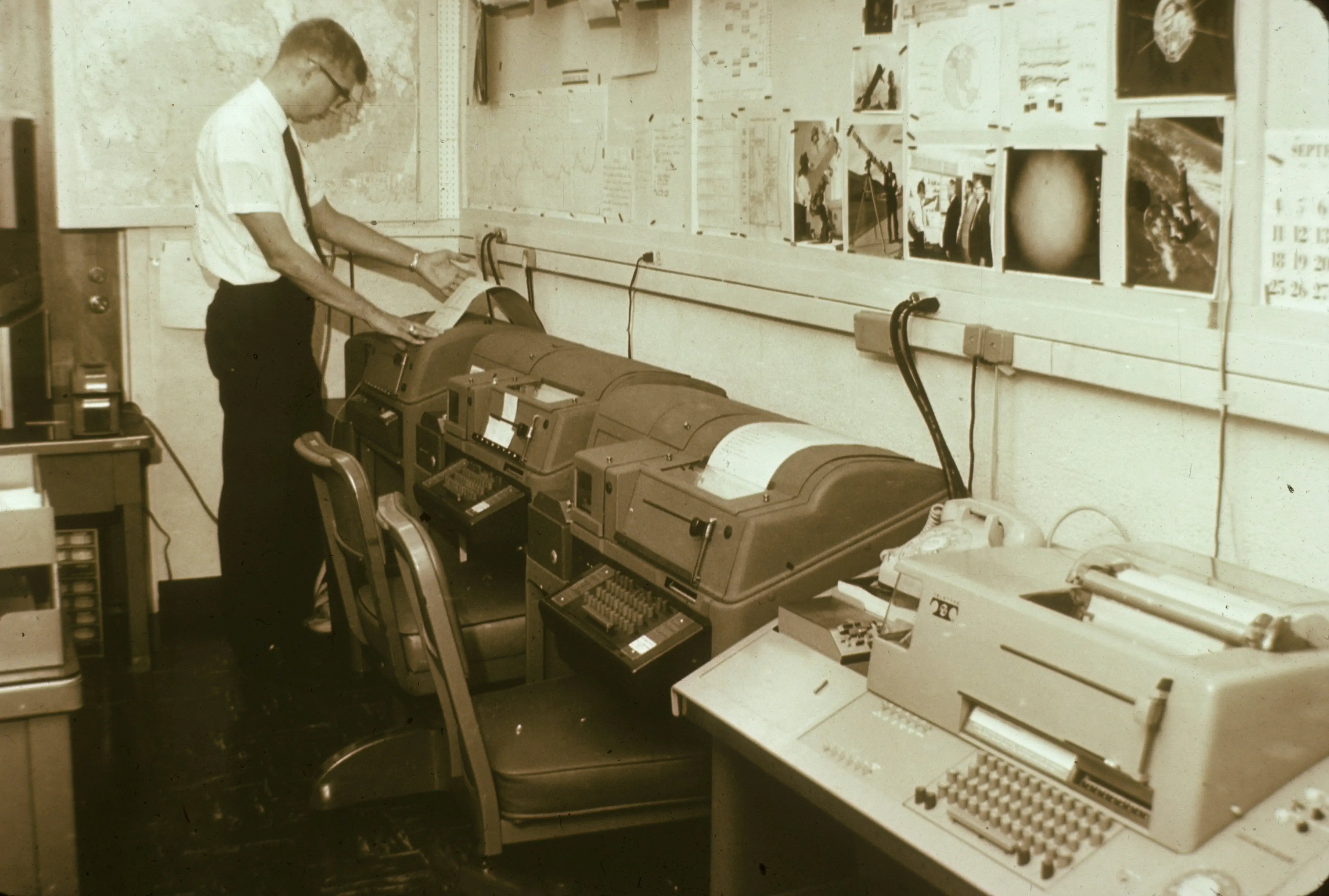

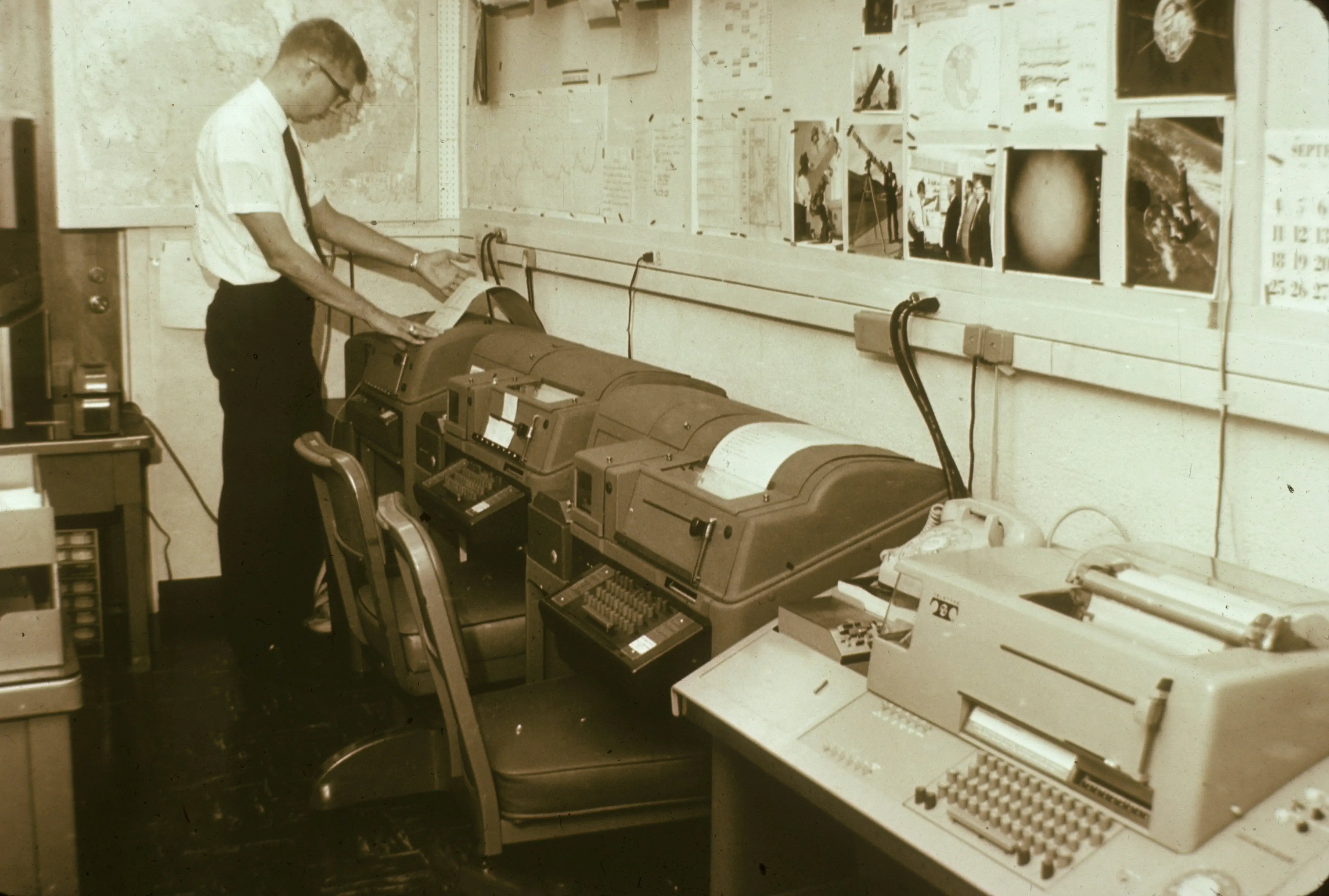

The laboratories of LCCP group are located in the Bovisa Campus of Politecnico di Milano and cover more than 2200 m2. They comprise laboratories for catalyst preparation and characterization, for catalytic testing under atmospheric pressure and high-pressure, as well as computational facilities.

Overview

The LCCP group benefits from a comprehensive research infrastructure that integrates experimental and computational capabilities. The laboratories support a wide range of activities, from catalyst synthesis and material characterization to testing under diverse operating conditions. Complementing these, computational facilities provide the tools for modeling, simulation, and data analysis.

Our numbers

lab spaces

office spaces

experimental rigs

available CPUs

The laboratories are equipped for the preparation, drying and activation of powder catalysts, structured catalysts and coatings. Available equipment includes mixers, pH-meters, precision balances, filtering systems, ball mills, dip-coating, spin-coating and spraying devices, an ultrasound bath and an ultracentrifugation unit.Catalyst activation is carried out in drying muffles, calcination ovens (seven units operating up to high temperature, including vacuum systems) and flow reactors with controlled atmosphere. Two 3D printers are used for the synthesis of advanced structured catalysts. An automated screen printer, equipped with a precision positioning system, enables the reproducible deposition of electrode layers on ceramic solid oxide cells.

The laboratories are equipped for the physico-chemical, morphological and surface characterization of catalytic materials. Available instruments include a laser granulometer for particle size distribution, BET and mercury intrusion porosimetry for textural analysis, and TPD/R/O and chemisorption units for surface studies. FT-IR, Raman and UV-Vis are also available. Catalyst reactivity is evaluated using thermogravimetric systems coupled with online mass spectrometry, and a rheometer is employed to determine the viscosity of catalytic slurries. Other characterization methods (e.g. SEM-EDS, TEM, NMR are available within the department/university.

The laboratories for operando catalyst characterization are equipped with spectroscopic instruments for in-situ and operando analyses under reaction conditions. Available techniques include FT-IR, Raman, UV-Vis and X-ray diffraction (XRD), enabling the qualitative and quantitative analysis of structure and surface properties of catalytic materials during operation.

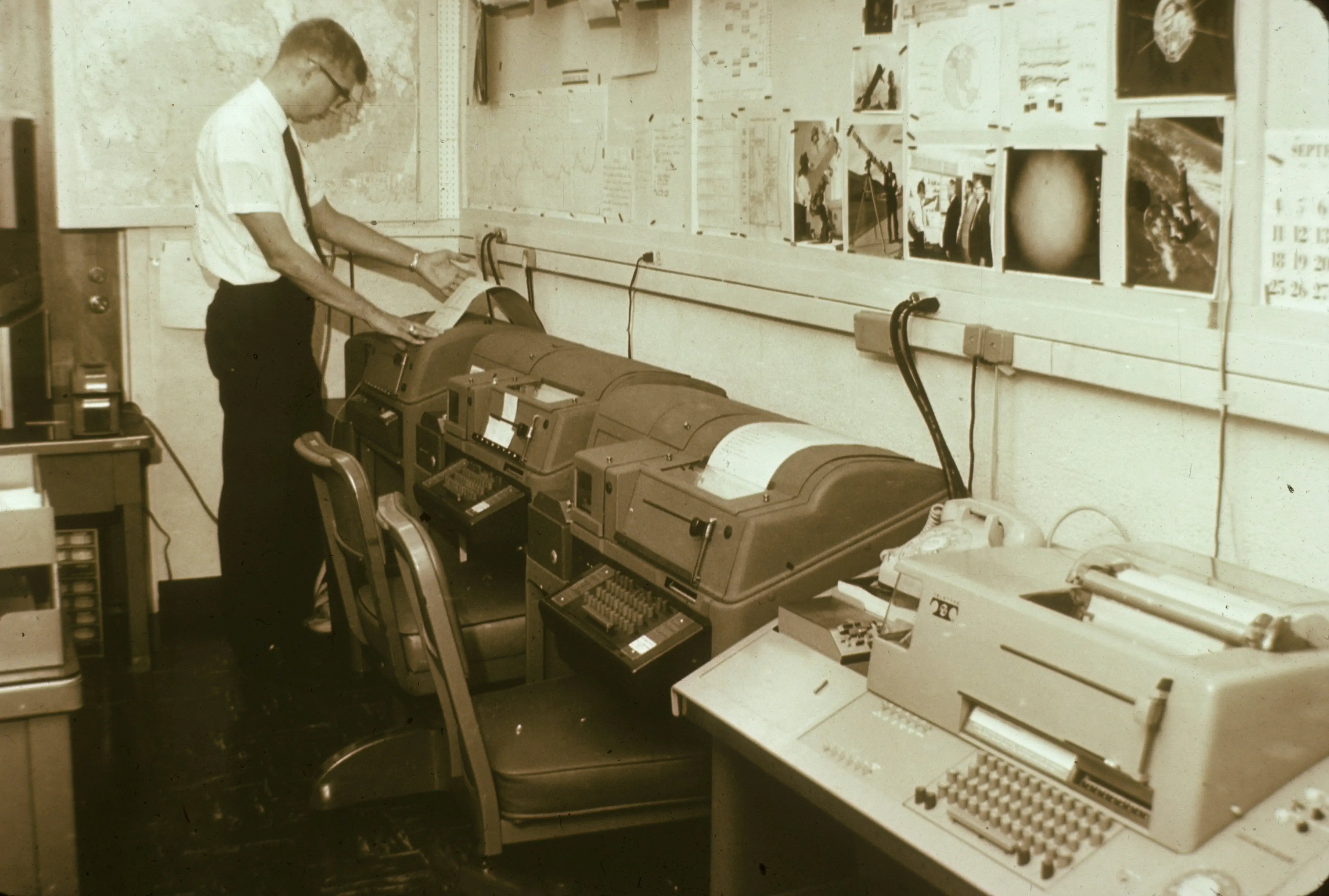

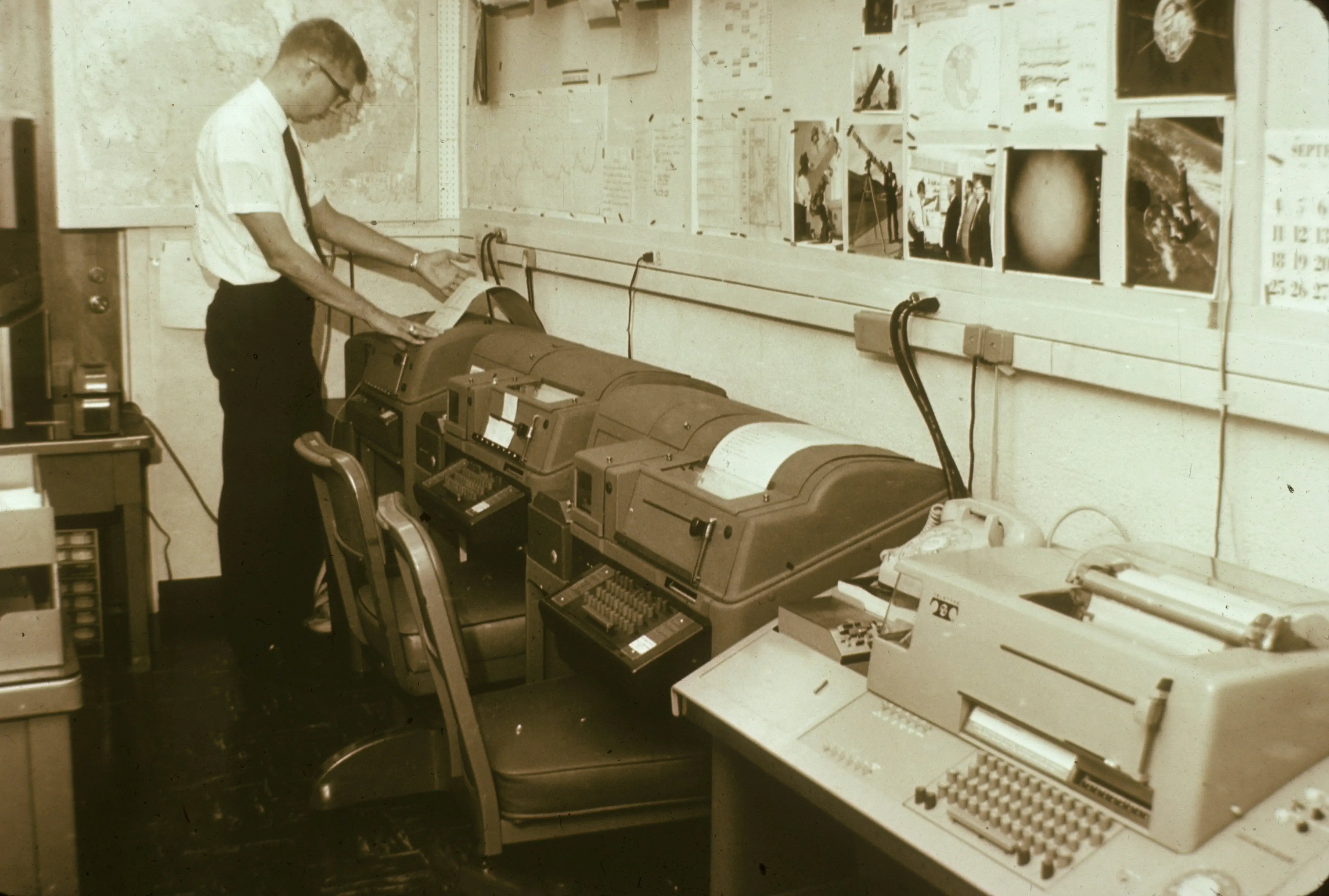

More than 30 experimental rigs are dedicated to the testig of catalysts in different morphologies. Overall equipped with up to 15 gas chromatographs (GC), 8 mass spectrometers (MS), 2 GC-MS, 4 FT-IR analyzers,12 specific gas analyzers, 3 potentiostat/galvanostat units, and 1 solar simulator. These facilities enable the evaluation of catalytic activity and selectivity under a wide range of operating conditions and reaction environments, including experiments at atmospheric pressure and up to 100 bar. Dedicated setups are also available for the testing of electrified reactors, allowing the investigation of catalytic processes driven by electrical energy.

The Laboratory of Computational Catalysis has ample access to computational time at national and international supercomputing centers. It owns a state-of-the-art high performance computing system using a hybrid architecture that includes more than 500 CPUs. Moreover, it has access to dedicated softwares for electronic structure calculations, Computational Fluid Dynamics simulations, specific tools for kinetic and spectroscopic data analysis and frameworks for reactor analysis and design.